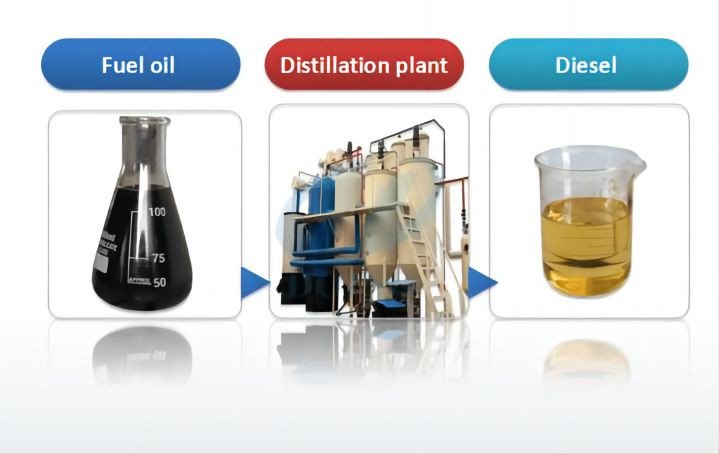

Recently, recycling and utilizing of waste oils have received significant attention all over the world, since waste lubricant oils are considered toxic and hazardous because of the presence of metal particles remaining from the additives such as phenols, compounds of zinc, chlorine and phosphorus, chlorinated compounds, polycyclic aromatic hydrocarbons and other residues. Waste materials of petroleum are exposed to various processes and then used as fuel or they are converted into various chemicals in order to minimize the harmful effects of these wastes. However, materials, such as sulfur, nitrogen chlorine and bromine found in waste oils are the most important factors making it difficult to recycle waste oils for various purposes including the production of fuel. The sulfur found in waste oils precipitates by undergoing a chemical reaction with metal oxide powders, such as zinc oxide (ZnO), iron oxide (Fe2O3) and copper oxide (CuO) in a certain temperature, so sulfuric acid can be decomposed from the oil. Waste oils can be reconstructed chemically by being heated in an oxygen-free environment. The most important advantage of this method is that it does not pollute the environment when carried out in an appropriate way. At present we are going to refine 9500 Metric Ton Waste Motor Oil per year and after refine we will get 80,00,000 Liter Diesel and 10,00,000 Liter Bitumin